Progressive Cavity Pumps (Eccentric screw pumps)

In addition to our drum pumps for low-viscosity and medium-viscosity products up to 1,000 mPas, we can also offer you a complete range of eccentric screw pumps (PC-pumps) for pumping highly viscous media that are still capable of flowing. Our high density solids pumps are constructed as eccentric screw pumps, so that the flow rate is determined by the geometry and the clearance between the rotating rotor (stainless steel screw conveyor) and the stationary stator (counter-rotating rubber or solid mixture).

ADVANTAGES OF THE ECCENTRIC SCREW PUMP (Progressive Cavity Pumps)

- Very robust pump

- Highly suited for viscous or abrasive mediums

- Low pulsation

- Self-priming

- Reversible conveying direction

ECCENTRIC SCREW PUMPS AS DRUM AND CONTAINER PUMPS

With an electric motor or compressed air motor, the pumps are used for pumping low-viscosity to highly viscous substances up to 100,000 mPa s, preferably stationary, in a continuous operation.

The standard pumping rates are 12, 25 or 50 litres/min, the pumping pressures are 6 to 24 bar. We can also build a vertical version as a dosing pump with a small output.

ECCENTRIC SCREW PUMPS AS CONTAINER PUMPS

With an AC motor, three-phase motor or compressed air motor, the pumps are used for pumping low to highly viscous substances up to 100,000 mPas, preferably stationary, in a continuous operation (also ATEX certified).

The standard pumping rates are 80, 200 or 300 litres/min; the pumping pressures are 6 to 24 bar.

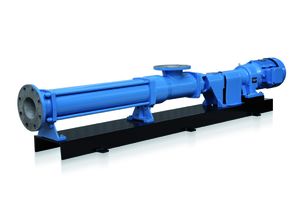

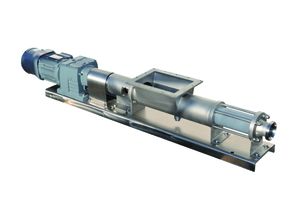

HORIZONTAL ECCENTRIC SCREW PUMPS

Pumping of liquids with low or high viscosity, neutral or aggressive, with or without solids or fibres.

In a block construction or as a version with bearing block.

Output: up to 500 m³/h; pressure levels: 6 to 48 bar.

Also available in a food grade version.

DRUM EMPTYING STATIONS

- Mobile and stationary drum emptying stations.

- Stationary drum emptying stations with follower plate for non-flowable mediums

- Filling plants with funnel

THE FOLLOWING MATERIALS ARE AVAILABLE FOR THE STATORS OF THE ECCENTRIC SCREW PUMPS

NBR black, max. 90°C, suitable for products containing oil and grease, alcohol and aqueous solutions.

Not resistant to acids, alkalis and solvents.

NBR white Perbunan, max. 90°C, suitable for products containing oil and grease, alcohol and foodstuffs.

Not resistant to acids, alkalis and solvents.

FKM, max. 160°C, high chemical resistance.

PTFE, max. 200°C, high chemical resistance, suitable for food, pharmaceutical and cosmetic products.

EPDM max. 110°C, good resistance to alkalis (undiluted and diluted), acids (diluted), ketones, alcohols. Food grade (complies with BGVV recommendations and in the composition of the FDA's positive list).

Not resistant to oils and fats. When milk (3.5% fat) is conveyed, sufficient stability is ensured.

AREAS OF APPLICATION

Wherever other pump types cause problems.

Sewage treatment plants, food and beverage industry, petrochemicals, pharmaceuticals, agriculture, paper and pulp industry